In the world of piping systems, flexibility is crucial for accommodating changes, maintenance, and expansions. Socket flanges play a significant role in enhancing the flexibility of these systems. This article explores how socket flanges contribute to a more adaptable, efficient, and reliable piping infrastructure.

1. Ease of Installation and Assembly

Socket flanges are designed for straightforward installation, making them an ideal choice for systems requiring frequent modifications or maintenance.

Key Features:

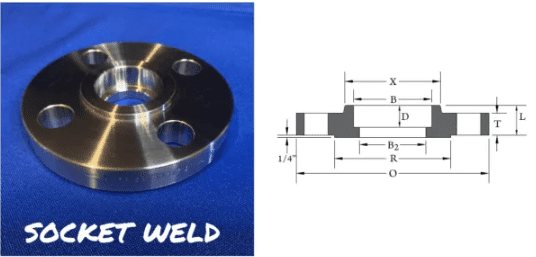

- Socket Weld Connection: Allows for easy alignment and welding, ensuring a secure and leak-proof joint.

- Minimal Preparation: Requires less preparation compared to other types of flanges, speeding up the installation process.

- Compatibility: Can be used with various pipe materials and sizes, enhancing system adaptability.

2. Facilitating System Modifications

One of the significant advantages of socket flanges is their ability to facilitate system modifications without extensive downtime.

- Modification Benefits:

- Quick Disassembly: Allows for easy disconnection and reconnection of piping segments.

- Adaptability: Enables quick changes in the piping configuration to meet new requirements.

- Maintenance Access: Provides straightforward access for inspection and repairs, minimizing system disruptions.

3. Accommodating Thermal Expansion and Contraction

Socket flanges help manage the thermal expansion and contraction of piping systems, which is vital for maintaining system integrity.

- Thermal Management:

- Flexibility: Allows for slight movement within the system to absorb thermal expansion.

- Stress Reduction: Minimizes the stress on piping joints and connections caused by temperature fluctuations.

- Durability: Enhances the lifespan of the system by preventing damage from thermal cycling.

4. Supporting Complex Piping Layouts

In complex piping layouts, flexibility is paramount. Socket flanges provide the versatility needed to navigate intricate piping designs.

- Layout Flexibility:

- Versatile Connections: Can be used in various orientations and angles to fit the system layout.

- Space Efficiency: Ideal for tight spaces where maneuverability is limited.

- Custom Solutions: Allows for custom configurations to meet specific project requirements.

5. Enhancing System Safety and Reliability

Flexibility in a piping system directly correlates to enhanced safety and reliability. Socket flanges contribute to these aspects by providing secure and adaptable connections.

- Safety Benefits:

- Leak Prevention: Ensures tight, secure connections that prevent leaks and spills.

- Reduced Maintenance Risk: Simplifies maintenance procedures, reducing the risk of accidents during system servicing.

- System Integrity: Maintains the integrity of the piping system under various operational conditions.

6. Cost-Effective Solutions

The flexibility offered by socket flanges can lead to cost savings in both installation and long-term maintenance.

- Cost Savings:

- Reduced Labor Costs: Easier and quicker installation reduces labor expenses.

- Lower Maintenance Costs: Simplified maintenance and repair processes minimize downtime and associated costs.

- Extended System Lifespan: Enhances the overall lifespan of the piping system, reducing the need for frequent replacements.

Conclusion

Socket flanges are a crucial component in enhancing the flexibility of piping systems. Their ease of installation, ability to facilitate system modifications, accommodation of thermal expansion, support for complex layouts, and contribution to system safety and reliability make them an invaluable choice for various applications. At [Your Company Name], we provide high-quality socket flanges designed to meet the diverse needs of modern piping systems. Contact us today to learn more about our products and how they can benefit your projects. Visit: https://www.texasflange.com/