System reliability is a critical factor in ensuring the smooth operation of industrial processes, minimizing downtime, and reducing maintenance costs. High-performance socket flanges play a significant role in enhancing the reliability of piping systems. This article explores how these specialized flanges contribute to system reliability and the benefits they offer.

1. Superior Material Quality

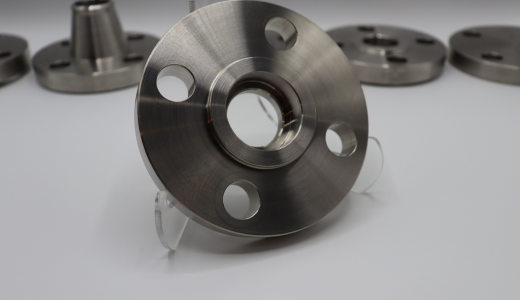

High-performance socket flanges are manufactured using top-grade materials that ensure durability and resistance to harsh operating conditions.

- Key Materials:

- Stainless Steel: Offers excellent corrosion resistance and mechanical strength.

- Alloy Steel: Combines durability with resistance to wear and tear.

- Nickel Alloys: Provide superior resistance to high temperatures and corrosive environments.

- Benefits:

- Longer Lifespan: High-quality materials reduce the need for frequent replacements.

- Improved Safety: Resistant to corrosion and degradation, ensuring safe operation.

2. Enhanced Design Features

High-performance socket flanges incorporate advanced design features that enhance their functionality and reliability.

Design Innovations:

- Precision Machining: Ensures accurate dimensions and a perfect fit, reducing the risk of leaks.

- Reinforced Structures: Designed to withstand high pressure and temperature conditions.

- Smooth Bore: Promotes better fluid flow and reduces turbulence.

- Benefits:

- Leak Prevention: Tight, secure connections prevent leaks and system failures.

- Efficiency: Improved fluid dynamics enhance system efficiency.

3. Robust Welding Capabilities

Socket flanges are known for their robust welding capabilities, which contribute to the overall strength and reliability of the connection.

Welding Advantages:

- Fillet Welds: Provide a strong, leak-proof seal.

- Ease of Welding: Simplifies the welding process, reducing the potential for errors.

- Stress Distribution: Evenly distributes stress across the joint, enhancing durability.

- Benefits:

- Structural Integrity: Strong welds ensure the flange remains secure under high stress.

- Maintenance Reduction: Robust connections minimize the need for frequent maintenance.

4. Compatibility with Diverse Applications

High-performance socket flanges are versatile and can be used in a variety of industrial applications, contributing to system reliability across different sectors.

Common Applications:

- Oil and Gas: Suitable for high-pressure and high-temperature environments.

- Chemical Processing: Resistant to corrosive substances and chemical exposure.

- Power Generation: Can withstand extreme thermal cycling and pressure variations.

- Benefits:

- Versatility: Suitable for a wide range of applications, reducing the need for multiple flange types.

- Reliability Across Sectors: Ensures consistent performance in various industrial settings.

5. Compliance with Industry Standards

High-performance socket flanges are designed to meet stringent industry standards and certifications, ensuring their reliability and safety.

Standards:

- ASME (American Society of Mechanical Engineers): Ensures the flange meets specific quality and performance criteria.

- ANSI (American National Standards Institute): Provides guidelines for dimensional accuracy and compatibility.

- ISO (International Organization for Standardization): Ensures global compatibility and quality assurance.

- Benefits:

- Quality Assurance: Compliance with standards guarantees high quality and reliability.

- Global Compatibility: Standardized flanges can be used in international projects.

6. Proactive Maintenance and Monitoring

Implementing high-performance socket flanges allows for easier maintenance and proactive monitoring, further enhancing system reliability.

Maintenance Strategies:

- Regular Inspections: Easier to inspect for signs of wear or damage.

- Predictive Maintenance: Advanced materials and design features support the implementation of predictive maintenance programs.

- Remote Monitoring: Integration with sensors for real-time condition monitoring.

- Benefits:

- Reduced Downtime: Early detection of issues prevents unexpected failures.

- Cost Savings: Proactive maintenance reduces long-term repair and replacement costs.

Conclusion

High-performance socket flanges are essential for enhancing the reliability of piping systems. Their superior material quality, advanced design features, robust welding capabilities, versatility, compliance with industry standards, and support for proactive maintenance all contribute to a more reliable and efficient system. At [Your Company Name], we offer a range of high-performance socket flanges designed to meet the rigorous demands of various industrial applications. Contact us today to learn more about how our products can enhance the reliability of your piping systems.

Visit: https://www.texasflange.com/