Selecting the appropriate flange type for your piping system is crucial to ensure optimal performance, safety, and durability. Two common flange types are socket weld flanges and butt weld flanges. This article will explore the key differences between these flanges, helping you make an informed decision for your project.

1. Design and Structure

Understanding the fundamental design and structural differences between socket weld and butt weld flanges is essential.

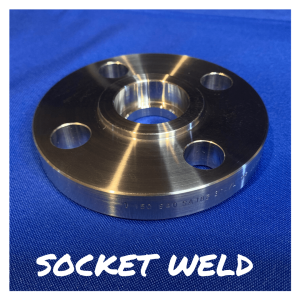

- Socket Weld Flanges:

- Design: Feature a socket where the pipe is inserted and then welded around the top.

- Structure: Suitable for small-diameter, high-pressure piping systems.

- Connection: Provides a smooth bore and better fluid flow within the pipe.

- Butt Weld Flanges:

- Design: Require the pipe to be beveled and then welded on the outside for a smooth, continuous connection.

- Structure: Ideal for larger-diameter, high-pressure piping systems.

- Connection: Creates a seamless, permanent joint that is stronger than the pipe itself.

2. Installation Process

The installation process varies significantly between socket weld and butt weld flanges.

- Socket Weld Flanges:

- Ease of Installation: Generally easier and quicker to install due to the simple welding process.

- Alignment: Requires careful alignment to ensure the pipe is fully inserted into the socket.

- Welding: Involves fillet welds, which are simpler and less time-consuming.

- Butt Weld Flanges:

- Installation Complexity: Requires precise alignment and preparation of the pipe ends, making the installation process more complex.

- Welding: Involves butt welding, which requires skilled labor and specialized equipment.

- Inspection: Typically requires radiographic or ultrasonic inspection to ensure weld quality.

3. Performance and Strength

The performance and strength of the flange joints are crucial factors to consider.

- Socket Weld Flanges:

- Strength: Provides adequate strength for small-diameter, high-pressure applications.

- Fatigue Resistance: May not be suitable for systems subjected to cyclic loading or high thermal stress due to potential stress concentrations.

- Leakage Potential: Lower risk of leakage if welded properly, but not as strong as butt weld joints.

- Butt Weld Flanges:

- Strength: Offers superior strength, making it ideal for high-pressure, high-temperature applications.

- Fatigue Resistance: Better suited for systems with cyclic loading or high thermal stress.

- Leakage Potential: Creates a seamless joint with minimal leakage risk, ensuring high integrity.

4. Applications and Suitability

Different applications and operational conditions dictate the suitability of socket weld and butt weld flanges.

- Socket Weld Flanges:

- Best For: Small-diameter pipes (typically 2 inches or less) and high-pressure applications where disassembly is not frequently required.

- Common Uses: Industrial piping, chemical processing, hydraulic systems, and high-pressure steam lines.

- Butt Weld Flanges:

- Best For: Larger-diameter pipes and systems requiring high strength and durability.

- Common Uses: Oil and gas pipelines, power plants, heavy-duty industrial applications, and high-temperature systems.

5. Cost Considerations

The cost implications of choosing between socket weld and butt weld flanges can influence your decision.

- Socket Weld Flanges:

- Initial Cost: Generally lower initial cost due to simpler installation and less labor-intensive welding.

- Long-Term Cost: May incur higher maintenance costs if the system is subject to fatigue or thermal cycling.

- Butt Weld Flanges:

- Initial Cost: Higher initial cost due to the need for skilled labor, precise alignment, and inspection.

- Long-Term Cost: Lower maintenance costs due to the superior strength and durability of the joint.

Conclusion

Choosing between socket weld and butt weld flanges depends on your specific project requirements, including pipe size, pressure ratings, operational conditions, and budget. Socket weld flanges are ideal for small-diameter, high-pressure applications, while butt weld flanges offer superior strength and durability for larger-diameter, high-pressure systems. At [Your Company Name], we provide a wide range of high-quality socket weld and butt weld flanges to meet your project needs. Contact us today to learn more about our products and how we can support your piping system requirements. Visit: https://www.texasflange.com/